Supplier Relationship Management: Strategies & Tools

It’s hard to think of a company that could truly produce and deliver goods and services on its own.

In reality, most rely on a complex web of supply chain relationships that work together to create the end product for consumers — from primary producers like farmers or mining companies to processing plants and manufacturers that make and assemble components, and the trucks, ships, and trains that transport everything from one place to another.

Avoiding disruption to this supply chain is critical.

Even a slight breakdown can lead to higher costs, significant delays, and quality issues. We’ve seen plenty of examples of this in recent years with disruptions caused by the COVID-19 pandemic, financial crises, data breaches, staffing challenges, and various global conflicts that remain ongoing.

And although companies can’t necessarily avoid every supply chain disruption, they can take steps to minimize potential problems and maximize resilience by carefully managing their supplier relationships.

So, let’s take a closer look at supplier relationship management and some strategies for successfully managing relationships with suppliers.

What is Supplier Relationship Management?

Supplier relationship management refers to the strategically planning, building, and maintaining relationships within an organization’s supply chain.

Your supply chain might include primary producers, manufacturers, importers, distributors, transport providers, sub-contractors, technology providers, and electricity/water companies.

For many companies, healthy relationships with each of these suppliers is critical to ensuring the business can:

- Operate as usual and meet their commitments

- Accurately plan their activities

- Minimize risk and ensure compliance

- Identify legal, ethical, privacy, or security issues in the supply chain

- Ensure quality outputs

- Maximize value (for all parties)

- Coordinate with different people and groups

- Negotiate contracts and manage agreements

- Collaborate or innovate on products or designs

- Create an early warning system to quickly find and put out (metaphorical) fires

- Streamline processes and keep things running smoothly

- Maintain or improve their reputation

- Find an edge over their competitors

With an increasingly global supply chain and complex global environment, managing supplier relationships is both more complicated and more important than ever. At the same time, changing stakeholder expectations are adding more pressure, with many companies expected to deliver more innovation and in less time.

So, how can you manage your supplier relationships? We’ve got nine strategies for you to consider…

9 Strategies for Managing Supplier Relationships

1. See Interactions as Relationships

First of all, it’s important to create a shift in your thinking around your suppliers. Instead of simply interacting with suppliers here and there, you need to start focusing on the bigger picture — your long-term relationships. Because each interaction and touch point contributes to your relationships, it’s important to start seeing your supplier interactions in a more strategic way.

2. Track Every Interaction

Following on from the first point, in order to see your bigger picture relationships, you’ll need to track every supplier interaction and touch point. Record your emails, phone calls, meetings, agreements, and more into a supplier relationship management system.

Of course, an added benefit of tracking each interaction in one place is that it can make it easier for multiple staff members to collaborate on relationships. And you’ll also retain that information and value within your organization — even when those staff members inevitably move on.

3. Assign Responsibility

Is there a specific team or individual in your organization dedicated to supplier relationship management? If not, it’s a good idea to get clear on who is responsible for these tasks. Depending on the size of your organization and which team members interact most regularly with suppliers, supplier relationships might be best handled by an account manager or administrator.

However, in many cases, multiple functions will interact with multiple suppliers. In this case, you’ll need to ensure that each person is briefed on your supplier management system, ensuring that they follow a consistent process for tracking relationships, interactions, and more.

On that note, consider also enhancing the strength of your internal stakeholder relationships, as these will likely impact the strength of your relationships with external suppliers.

4. Ensure Visibility Into All Suppliers

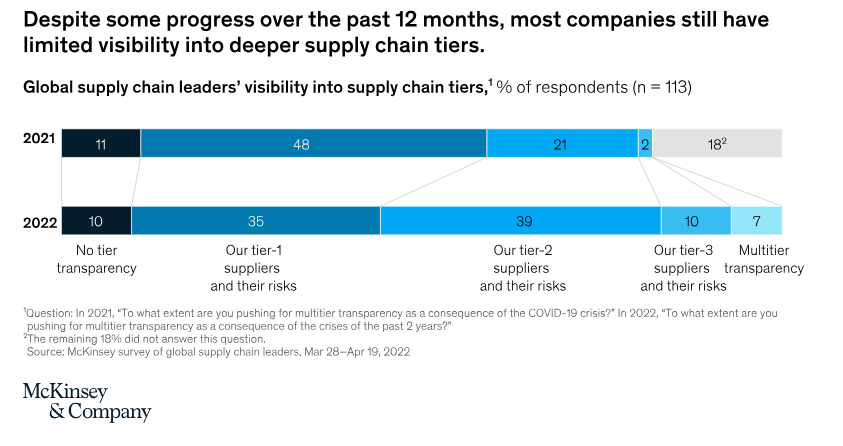

A Mckinsey survey found that the supply chain leaders who implemented end-to-end visibility dashboards were twice as likely to report having no challenges from 2022 supply chain impacts. Interestingly, some 45% of participants in the survey said they had no visibility into their upstream supply chain or could only see as far as their first-tier suppliers (though this was a significant improvement on the previous year). It’s clear that improving visibility is a huge opportunity for organizations that need to manage their supply chains.

Ideally, you should be able to see (at a glance) all your supplier relationships in one place — with important context around their importance to your organization and other factors that are relevant to you. In your tracking tool of choice, you might record supplier locations, costs, size, capabilities, performance, tier, and more. With all this information in one place, it’s much easier to analyze your situation, find and compare suppliers, and make critical decisions based on the facts that matter.

5. Segment Suppliers

Not all supplier relationships are created equal — you’ll likely need to pay closer attention to some, while you might only touch base with others on occasions. Use your supplier relationship management tools to group your suppliers in a way that suits your organization. For instance, you might create groups based on:

- Degree of impact on your operations

- How frequently you need to touch base

- Type of goods/services supplied

- Active/inactive suppliers

6. Track Relationship Health

Once you’re tracking your supplier relationships and interactions, the next step up is to track the health of your relationships. What makes a supplier relationship healthy? It might be…

- Recent communication between you and the supplier

- Frequent communication between you and the supplier

- Positive sentiment in your communication (you could use our AI sentiment analysis tool)

- Positive feedback

- Information sharing

- Relationships with multiple points of contact in the organization (you could identify this using relationship network mapping)

The right tools will make it easy to see how healthy your relationships are so that you can set targets, improve your communication, and build stronger relationships with suppliers.

7. Discover New Suppliers

Supplier relationship management can also extend to building relationships with new potential suppliers. This is especially important when you consider the potential for supply chain issues, problems with logistics, parts shortages, and more. These disruptions are perhaps the new normal, with 77% of recently surveyed executives acknowledging an adverse supply chain event in the previous year, and 44% anticipating further events in the next two years.

Discovering new suppliers can help build diversity and agility into your supplier relationships, which can future-proof your business. It’s always a good idea to have some back up sourcing options in case your primary supplier is unable to meet your usual requirements — and also to give you leverage to negotiate a more competitive deal.

8. Communicate Regularly

Do you have updates to share about an issue or opportunity that could impact your suppliers? Or could you benefit from more regular updates from them about delays, pricing changes, or product availability? One of the best things you can do is communicate more regularly.

By keeping the communication lines open and transparently sharing information when it’s available, it allows you to take action sooner that will mitigate risk and increase value for both sides.

9. Ask for Feedback

Finally, regularly asking for feedback is an excellent strategy for managing supplier relationships. Consider…

Have you recently asked your suppliers if there’s anything you can do to support them and ensure better collaboration, innovation, and other mutual benefits? Is there anything about your relationship or process that could be improved?

If you’re not sure, consider scheduling a call, sending out a survey, or simply asking them for feedback outright. Proactively asking for feedback will go a long way towards demonstrating your commitment to the relationship — and might even shine the light on some issues before they become serious.

Need Supplier Relationship Management Software?

Most or all of the above strategies are nearly impossible to implement without good supplier relationship management tools. If you’re in the market for new SRM software, why not consider Simply Stakeholders?

Our software is built for complex relationship management, tracking, analysis, and much more.

Best of all, our relationship management software is robust enough to handle all types of business and stakeholder relationships in one place — not just your supplier relationships.

Reach out to our team to organize a demo today.